As part of the Amphenol Group, we are a strong partner in meeting current and future requirements around plastic components and modules as well as housings for electrics and electronics in the automotive and other industries. We stand behind everything we do with passion. In doing so, we continuously evolve to contribute to our customers’ business success as a highly reliable and innovative partner. Using modern injection molding and assembly technologies, we are able to manufacture and supply high-quality products in the highest quantities at attractive prices.

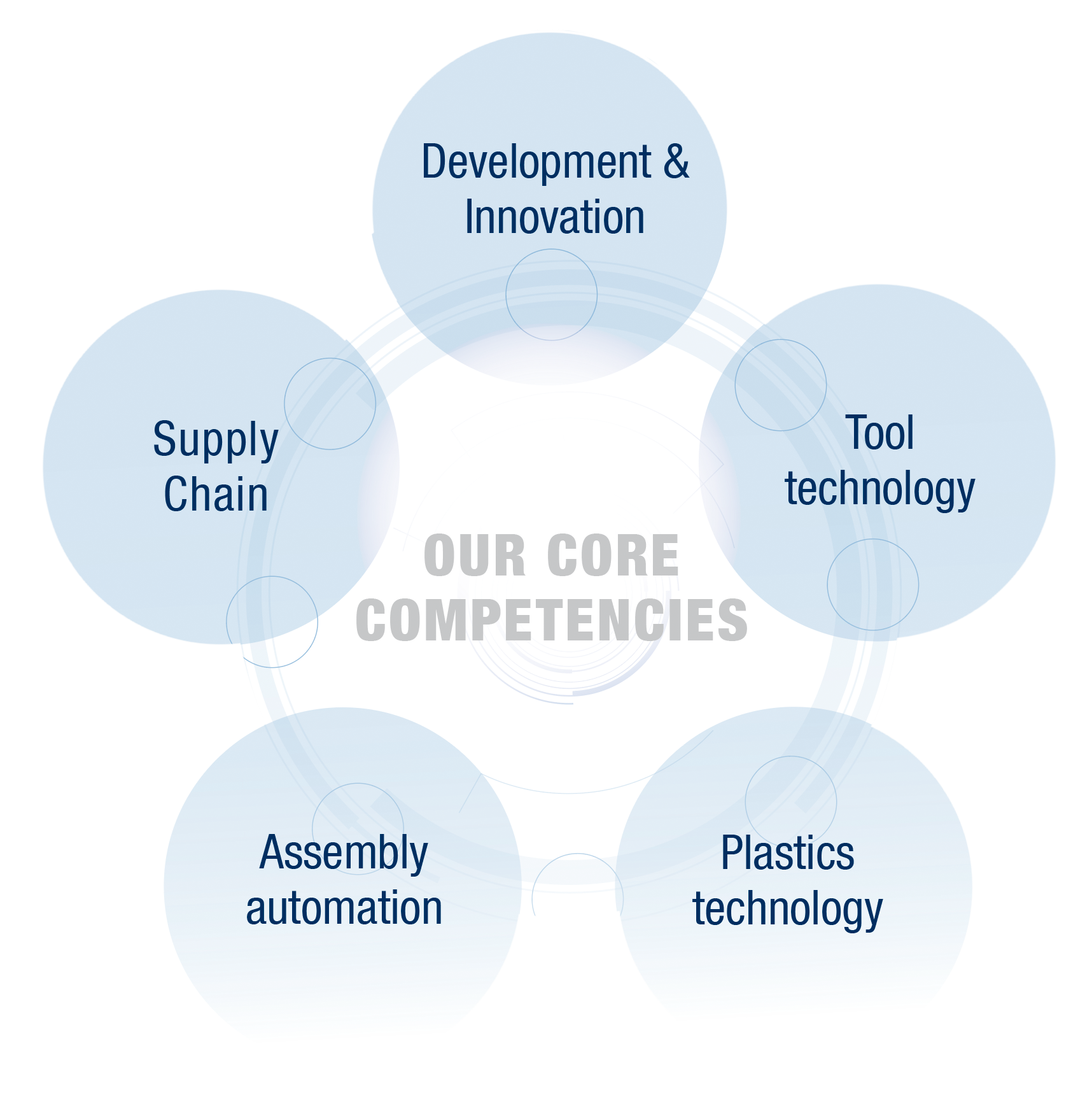

Development and Innovation

Mastering the core competencies “Product development” and “innovation” are essential prerequisites for the emergence of new, future-proof products. We offer the range from pure contract manufacturing of pre-engineered parts to product development and the development of new injection molding and assembly technologies to series production readiness.

As an innovation partner, we realize solutions for the implementation of product requirements in close cooperation with our customers.

Together with partners in our research and development networks, we work on innovative topics related to plastic injection molding and assembly technology for new applications, such as through function integration and multi-component injection molding.

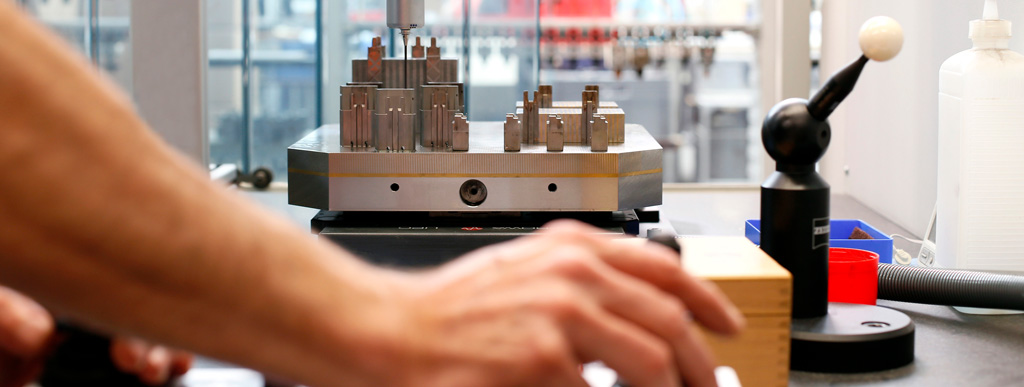

Tool Technology

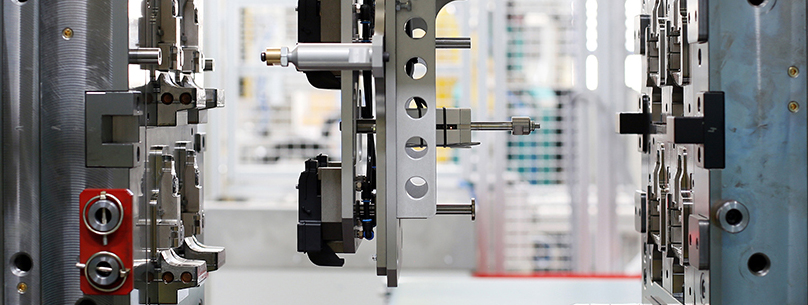

Using innovative technologies, we not only design parts, but also build highly complex injection molds. Our core competencies in mold making are primarily focused on high cavities in most demanding tolerance ranges.

Innovative technologies such as multi-component injection molding and overmolding of inserted parts are also applied / used here. We are your contact for tools – from prototype tools to series tools.

Plastics Technology

We produce over two billion plastic parts per year using more than 200 state-of-the-art injection molding machines and high-cavity molds. Highly efficient processes, supported by robot technology for inserting and removing various components, ensure maximally short throughput times. However, not only production, but also the entire process chain from material preparation and setup to manufacturing, packaging and delivery of the products , is trimmed for efficiency.

The materials to be processed are made available to production just in time. A wide variety of plastic materials, with or without fillers, are used by us as required.

These diverse components are processed with the aid of sustainable technologies. Special processes such as multi-component injection molding or overmolding technologies complement our core competencies. For highly complex assembly processes, we use specialized production cells with integrated injection molding that are tailored to the product, so that we can also manufacture multi-part assemblies inline. Quality and quantity of the manufactured products are ensured.

With our many years of experience in injection molding and assembly technology, we are able to adapt all factors in the manufacture of products to the wishes of our customers. This is always done with a view to continuous optimization.

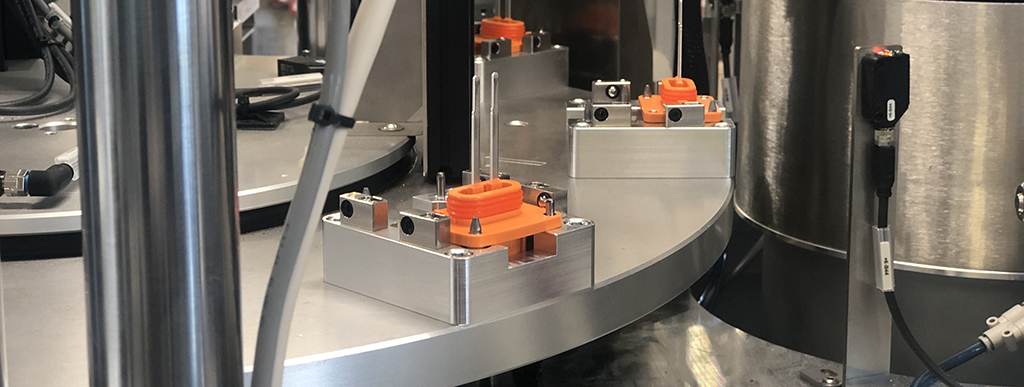

Manufacturing Technologie

In addition to plastics processing, the highly automated assembly of our components is another core competence of FEP.

In addition to over 100 automatic assembly machines for connectors and sensors, we also have several highly automated, interlinked systems for the assembly of oil pressure switches. In order to ensure optimum quality, all our automatic assembly machines are equipped with the latest image processing technology.

The combination of various production technologies in the manufacture and assembly of our articles has always characterized our competitive advantage.

Supply Chain

In addition to efficient production, logistics also plays a key role in establishing a holistic and value-adding production system. Growing customer requirements along the entire value chain are constantly prompting us to critically scrutinize existing processes and to optimize material flows.

With the help of a chaotic warehouse system and organized supplier management, controlled by a warehouse management system, we use our capacities effectively, facilitating the handling of several million products daily. Automated logistics processes put us in a position to increase the speed of response as well as adaptability in terms of customer-oriented order commissioning.